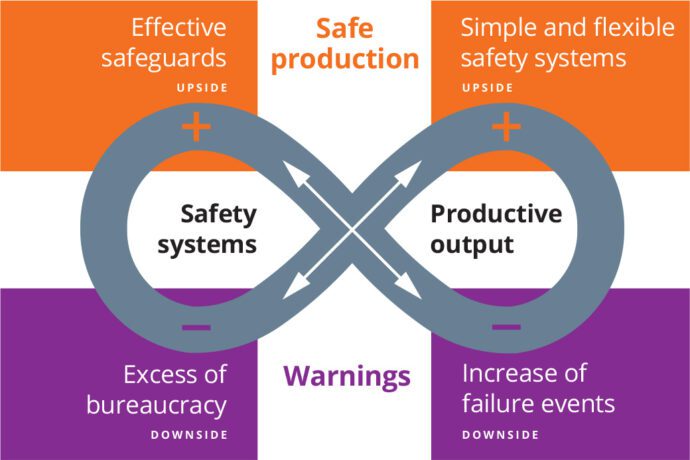

There will always be polarities that challenge leaders’ decisions; one clear and old example is safety versus productive output. This can be seen as polarity to be managed instead of a goal conflict to be resolved. Organisations need both, not just safety (or just production).

The following sequence provides an overview of polarity management (safety systems versus productive output):

- Favouring productive output very often leads to an increase in failure events (accidents or near misses).

- Leaders often respond to this by increasing the focus on safety systems (managing or implementing effective safeguards).

- If there is too much attention to safety systems, this can result in excessive bureaucracy that very often compromises productivity.

- Leaders often respond to this by favouring productive output and giving people flexible procedures and liberties while releasing some boundaries. This cycle repeats itself all the time.

Managing polarities needs clear and actionable indicators. These will inform organisational leaders whether they are starting to move towards the downsides, as well as the actions required to gain or maintain the positive benefits from the upsides.

Example of polarity management: