Steel and climate change – a three phase approach to industrial transformation

Andrew Purvis

Director, Safety, Health and Environment, worldsteel

5 December 2019

Recognising the critical role and impact of our products and production processes on greenhouse gas emissions, worldsteel and many of its members are participating at the United Nation’s annual climate change conference (COP).

As accredited observers of the UN process, many in the steel community will be speaking and participating in a number of forums and discussions.

worldsteel participates in a COP25 side event: Dialogue on Decarbonization without Deindustrialization on 4 December 2019

Our experience at previous COPs and ongoing conversations with our members, governments and international bodies have made it very clear that steel is an essential element of the low carbon transition. Without steel no society will be able to decarbonise; in essence we will make the green future possible.

This is all true, but in the past this is perhaps where we stopped talking. For a long time the message from our sector and many others was “you need us”, but this is no longer enough and this is not a credible position to hold in 2020.

As more and more countries recognise a “climate crisis” and civil society increases pressure on governments and individuals to act, we must and do recognise that addressing our own footprint is as important as the essential work our product will do to enable and support society in the transition to a low carbon future.

The world needs a sustainable steel sector able to provide the advanced materials that will enable us to manage in a rapidly changing world, and we need to change to make this possible.

Given the ubiquitous nature of steel, it probably wouldn’t surprise you to learn that last year, consumers around the world used some 1.7 billion tonnes of steel in buildings, transport, and a myriad of other applications.

Transforming such a behemoth of an industry will take time and immense effort, especially at a time when demand is expected to increase, but it can be done.

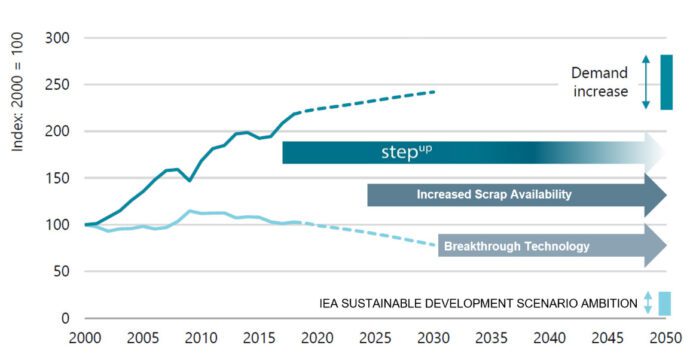

1. step up

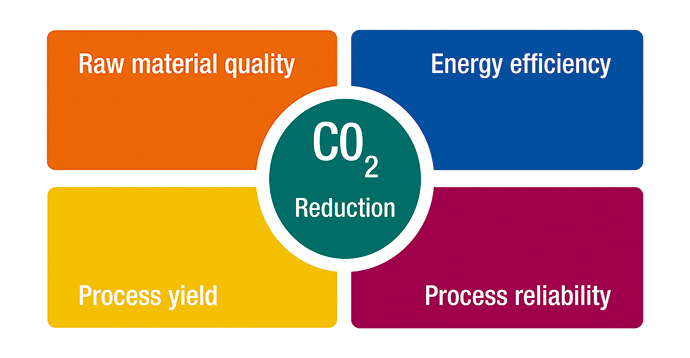

step up is a new industry wide four-stage efficiency methodology. This multistep process covering raw materials, energy input, yield and maintenance can be used to support improvements in mill operations to efficiency levels commensurate with the steel industry’s top performers.

Efficiency is key to ensuring every tonne of steel produced has the lowest possible environmental and greenhouse gas impact.

step up: A four stage efficiency methodology

2. Increased scrap use

Steel is already highly recycled. About 630 million tonnes of scrap are recycled every year.

Scrap becomes available when steel reaches the end of its working life, which varies by application – from a few months for packaging steel to closer to 100 years for steel used in buildings.

In the decade 1998 – 2008 global steel production increased from around 800 million to 1.3 billion tonnes. In the next few decades much of this steel will reach the end of its life, and that which cannot be reused or remanufactured will be returned for recycling.

This injection of increased scrap steel will play a key role in reducing sector emissions.

3. Breakthrough technology

Ultimately, virgin steel (steel made from ore) will need to be produced in an entirely new and zero net greenhouse way. A number of worldsteel members and other research groups are developing exciting and promising new technologies.

This is very good news, as a portfolio of technologies will be required that can be applied in different conditions.

For example, in regions with an excess of cheap renewable energy, the best option might be electrolysis-based hydrogen reduction. While in regions with access to ample CO2 storage and infrastructure it may be that natural gas-based hydrogen or carbon capture and storage would make more sense. In other areas hybrids or entirely different approaches could be taken.

A common theme will be that steel produced using new low carbon technology will cost more to produce, and as new technology is deployed there will be a period when conventionally produced steel and new higher cost net zero steel compete in the same market.

During the transitional period it will be important that policy supports the transformation and enables rather than inhibits the very high levels of investment that will be necessary to create a steel industry fit for the challenges of the 21st century.