Declared product

The presented results refer to a declared unit of 1 metric tonne of finished cold rolled coil representing the Global industry average.

Product description

Obtained by heat treatment (annealing) and strain-hardening of cold rolled steel in a way to achieve final mechanical properties making the steel suitable for further uses (forming and bending); can be further processed. Classified into the following: formable steels, high strength formable steels, weathering structural steels, structural steels, hardenable steels. Applications include domestic applications, automotive applications, lighting fixtures, electrical components (stators, rotors) and various kinds of sections roofing applications, profiled sheets, wall elements, etc. Typical thickness between 0.3 – 3 mm. Typical width between 600 – 2100 mm.

Scope

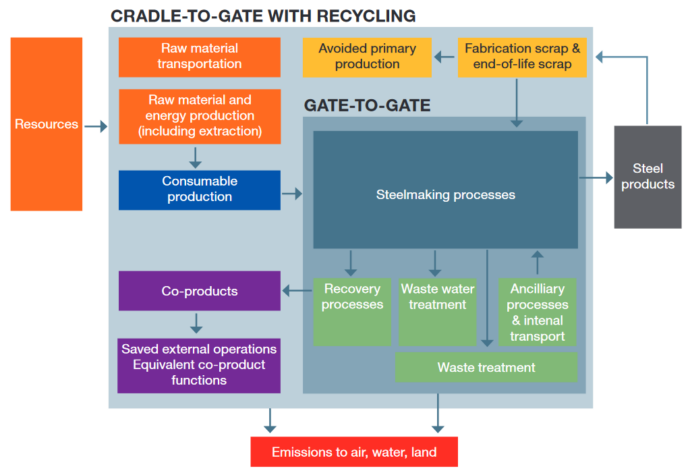

The assessment covers the cradle-to-gate LCA results of the declared steel products including end-of-life-recycling (see Figure 1).

The cradle-to-gate LCI study with end-of-life recycling includes net credits (the amount of end-of-life scrap minus any scrap consumed in the production of the product) associated with recycling the steel from the final products at the end-of-life (end-of-life scrap) with a 95% end-of-life recycling rate. This study does not include the manufacture of the downstream final products or their use.

The primary data collected from the steel companies relates to the production from 2017 to 2022 and is believed to be representative of global steel production during this time frame. 155 steel production sites from 43 companies have contributed to the 2022 worldsteel LCI data release. Allocation of environmental impacts between the steel product and resulting co-products follow the worldsteel methodology applying system expansion (see worldsteel 2022 LCI Study Report for further details).

Figure 1: System boundaries overview of the cradle-to-gate analysis including end-of-life recycling (worldsteel methodology report, 2017).

Figure 1: System boundaries overview of the cradle-to-gate analysis including end-of-life recycling (worldsteel methodology report, 2017).

The calculation is based on Sphera background data – LCA for Experts software version 10.7.0.183, database version 2022.2. Therefore, allocation in the supply chain follows the assumptions of the Sphera-database. Further information of the applied background data is given in the worldsteel 2022 LCI Study Report.

End-of-life allocation follows the approach defined according to worldsteel’s LCI methodology, whereby the net amount of scrap reaching the end-of-life stage is calculated. This is then reported separately to the cradle-to-gate impacts.

This evaluation complies with the requirements of ISO 14040 and ISO 14044.

It represents a basis for potential B2B and B2C communication of the environmental impacts of the analysed steel products.

LCA Results

The presented results refer to the life cycle related environmental footprint of 1 metric tonne of steel product. Table 1 presents the product’s potential environmental impact according to selected indicators following EF3.0 + energy and water indicators, given that this is a standard often used for construction products. The chosen indicators refer to the selection applicable for sustainable building certification according to the DGNB system.

Table 1: Results of the LCA – Environmental impact and indicators according to selected indicators of EF3.0 + energy and water indicators: 1 metric tonne of steel product

| Indicator |

Unit |

Cradle-to-gate results

[module A1-A3*] |

End of Life results

[module C1-C4*] |

Benefit of recycling results

[module D*] |

| Climate Change – total |

tonnes CO2 eq. |

2.66 |

4.83E-07 |

-1.45 |

| Climate Change, fossil |

tonnes CO2 eq. |

2.68 |

4.80E-07 |

-1.46 |

| Climate Change, biogenic |

tonnes CO2 eq. |

-0.0149 |

2.42E-09 |

0.0084 |

| Climate Change, land use and land use change |

tonnes CO2 eq. |

0.0004 |

2.57E-11 |

-0.0002 |

| Ozone depletion |

kg CFC-11 eq. |

1.05E-09 |

4.47E-16 |

1.89E-09 |

| Acidification |

Mole of H+ eq. |

6.1468 |

1.51E-06 |

-3.4451 |

| Eutrophication, freshwater |

kg P eq. |

0.0012 |

1.30E-09 |

-0.0003 |

| Eutrophication, marine |

kg N eq. |

1.1873 |

2.31E-07 |

-0.5534 |

| Eutrophication, terrestrial |

Mole of N eq. |

12.4837 |

2.58E-06 |

-4.9592 |

| Photochemical ozone formation, human health |

kg NMVOC eq. |

4.5886 |

1.15E-06 |

-2.2475 |

| Resource use, mineral and metals |

kg Sb eq. |

0.0004 |

7.33E-11 |

-0.0080 |

| Resource use, fossils |

GJ |

29.06 |

2.26E-05 |

-14.00 |

| Water use |

m³ world equiv. |

112 |

1.04E-05 |

-95 |

| Total use of renewable primary energy resources (PERT) |

GJ |

1.75 |

3.24E-07 |

0.55 |

| Total use of non-renewable primary energy resources (PENRT) |

GJ |

29.07 |

2.26E-05 |

-14.00 |

*Modular approach according to EN 15804.

Content of recycled steel

The total amount of iron and steel scrap used to make the product is 0.139 metric tonnes scrap/tonne of steel product.

In this case, the scrap input refers to the net scrap input, i.e., it does not consider the recirculating, internal or home scrap that is generated in the processes that are being studied, i.e., scrap from the finished cold rolled coil production process that goes back into the BOF or EAF is not included as an external scrap input for finished cold rolled coil.

Thus, the scrap input is often considered to be external to the production of the product as well as post-consumer scrap, i.e., scrap produced in processes downstream of the production of the steel product in question: on the steel plant, fabrication and manufacturing scrap as well as end-of-life scrap (see further information in the worldsteel methodology report, 2017).

References

EN 15804+A2:2019

EN 15804:2019-04+A2, 2021. Sustainability of construction works —

Environmental Product Declarations — Core rules for the product category of

construction products.

ISO 14040

ISO 14040:2006. Environmental management – Life cycle assessment – Principles

and framework.

ISO 14044

ISO 14044:2006-10. Environmental management – Life cycle assessment –

Requirements and guidelines.

worldsteel, 2017

World Steel Association, 2017: Life cycle inventory methodology report.

worldsteel, 2022

World Steel Association, 2022: 2022 LCI Study Report