Advanced high-strength steels (AHSS) are helping car manufacturers usher in an era of robust, lightweight vehicles that improve fuel efficiency and lower emissions without compromising on safety

This year’s new car models are set to be standard bearers for a generation of cars fortified by innovations from within the steel industry. In the US, ArcelorMittal Global R&D has assisted in the development of the AHSS used for the Jeep Grand Cherokee, as well as in the Ram pick-up truck, Pacifica minivan and the Jeep Wrangler.

“Our customers are looking to ArcelorMittal to produce new grades of advanced high-strength steel that are stronger and more formable so they can manufacture a lighter weight vehicle without compromising safety”

Jim Loch, Fiat Chrysler

This steel, known as GI TRIP 690, was originally imported from Europe, but the R&D centre based in east Chicago can now locally provide this AHSS to Jeep and other US car manufacturers, such as Fiat Chrysler.

Oleg Yakubovsky, ArcelorMittal Global R&D’s lead scientist on the development of the new grade, underlined the steel industry’s desire to push the boundaries of what steel can deliver and produce lighter and stronger vehicles in the process. He said, “Our success with GI TRIP 690 will help us move forward on even more challenging advanced high-strength steel grades.”

“Our customers are looking to ArcelorMittal to produce new grades of advanced high-strength steel that are stronger and more formable so they can manufacture a lighter weight vehicle without compromising safety,” said Fiat Chrysler Automobiles Account Manager Jim Loch.

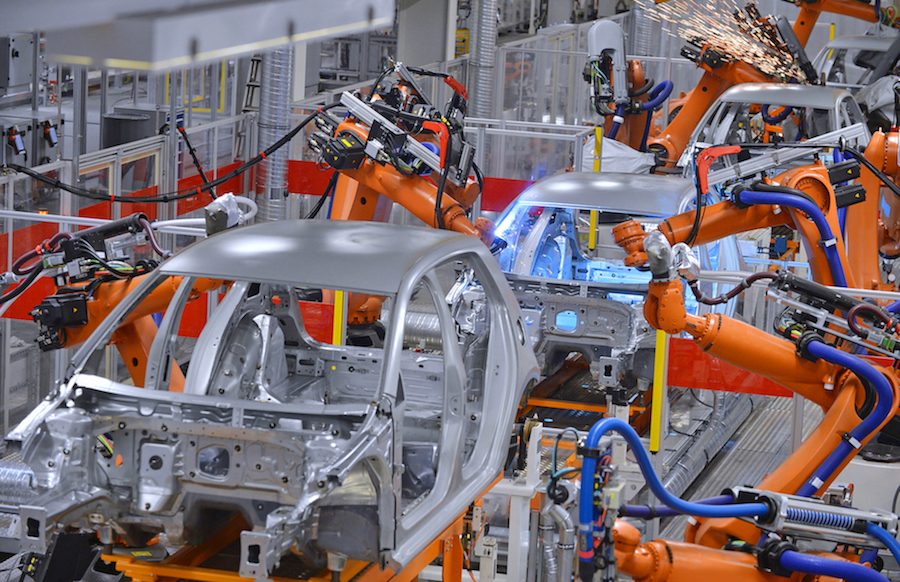

Advanced high-strength steels can lower weight without compromising on safety

Advanced high-strength steels can lower weight without compromising on safety

Safety first?

Customer desire for safety is a key driver in the widespread adoption of AHSS. A 2018 survey found that 75% of consumers regard safety as the deciding factor when choosing a vehicle. AHSS helps meet this demand, while allowing manufacturers to avoid raising costs or adding bulk to their vehicles, which negatively impacts fuel efficiency and tailpipe emissions.

Car makers across the planet are embracing the benefits of these new steels, with Hyundai’s new i30 nearly doubling the amount of AHSS in its construction compared with the older model.

Hyundai Steel, who provide the materials for the Hyundai Motor Company, use specialised heat treatment processes to create AHSS that is twice as rigid and 10 per cent lighter than conventional steel. With 53.5 per cent of the i30 being made of AHSS, the car has increased static rigidity while shedding 28kg in body weight.

The 2019 Ram 1500 – which is the North American Truck of the Year – is also comprised of 98 per cent AHSS in its frame, adding durability and toughness while reducing weight by 45kg. The Ram’s truck bed and cab are also 54 per cent AHSS, contributing to the 2019 model being the strongest yet.

The 2020 Toyota Corolla, 2019 Subaru Forester and 2019 Mercedes-Benz G-class are all increasing the amount of AHSS used in their construction. The G-class has managed to lose an impressive 170kg, while the Corolla has improved torsional rigidity by 60 per cent compared with its predecessor.

The trend is moving steadily towards AHSS replacing conventional steels in vehicle manufacture, with research suggesting the market for advanced high-strength steel will grow from $13.1bn in 2016 to $29.1bn by 2023.

The choice for car manufacturers is clear. If the question is how to improve fuel efficiency and reduce emissions, while not compromising on safety or increasing costs, then advanced high-strength steels are the answer.

Images: iStock